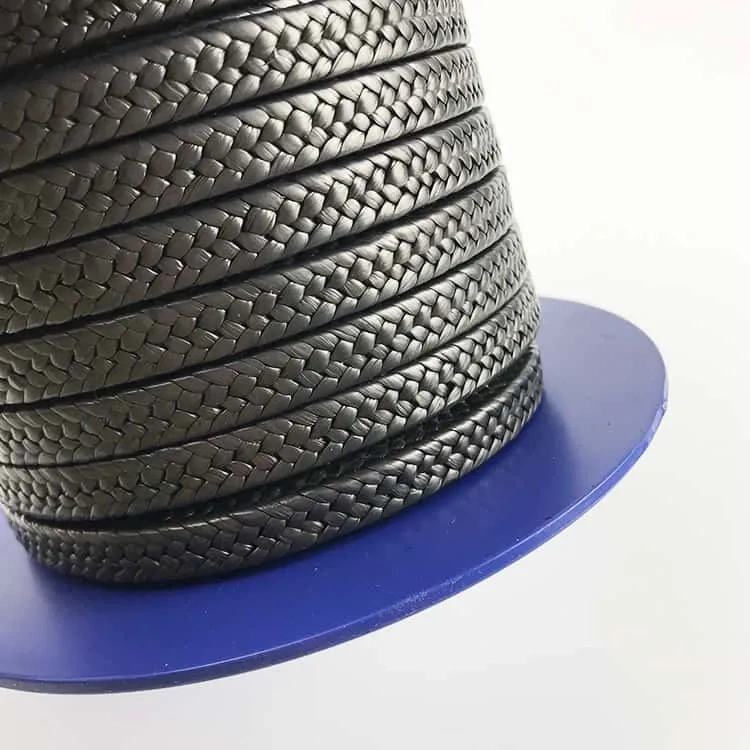

The English name of Gland Packing is used to seal the shaft in order to solve the dynamic sealing structures, preventing the loss of fluid from around the shaft. In rotary motion the insertion braid plays an important role in the efficiency of pumps, mixers, valves and other industrial equipment. Braided wire inserts have long been the traditional sealing solution for many industries because of its versatile nature. Nowadays, with more stringent requirements on technical requirements, and the use of more media, the insertion braid is very diverse in manufacturers.

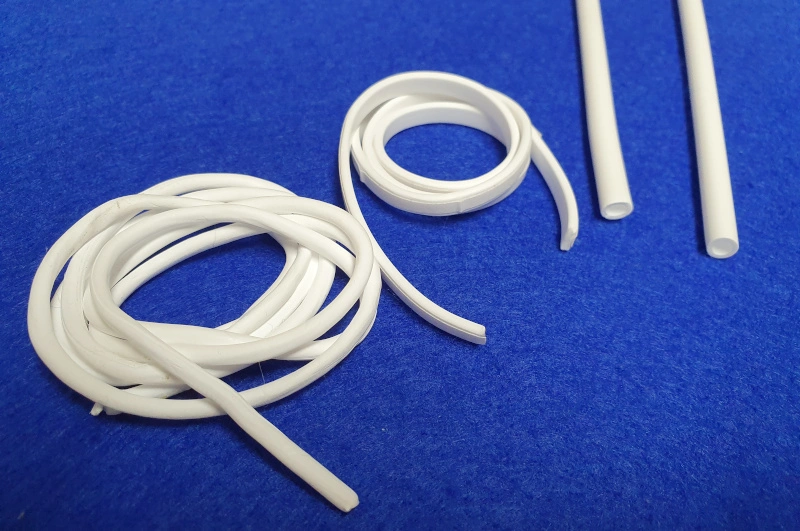

We all know PTFE, the grandfather of fluoroplastics, but what is expanded PTFE? Also known as ePTFE, expanded PTFE is the microporous version of PTFE. ePTFE enjoys similar properties to PTFE and is perfect for any applications that require a permeable PTFE material.PTFE unique properties:

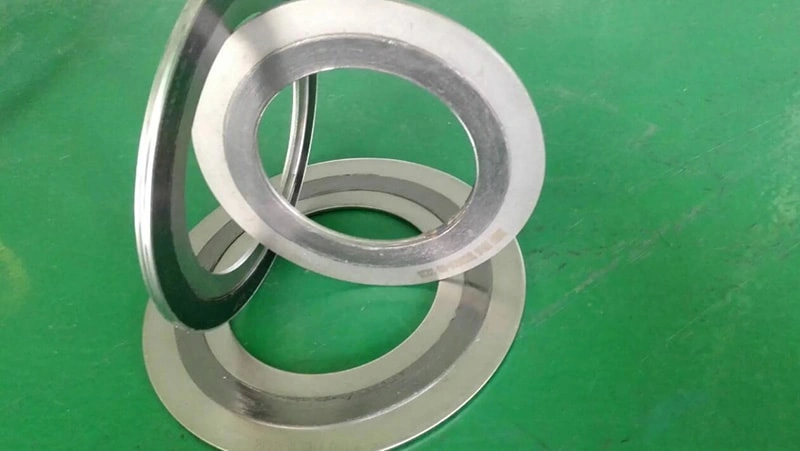

Commonly used gaskets include non-metallic gaskets, semi-metallic gaskets, and metallic gaskets.

Pure Graphite PTFE Packing is a high-performance sealing material that combines the exceptional chemical resistance and low friction properties of PTFE (polytetrafluoroethylene) with the outstanding thermal conductivity and self-lubricating capabilities of pure expanded graphite. Engineered through an advanced composite manufacturing process, this material delivers superior sealing reliability for dynamic and static applications under extreme conditions, including high temperatures, aggressive chemicals, and high-pressure environments. It is widely used in pumps, valves, mixers, and reactors across industries such as chemical processing, pharmaceuticals, food and beverage, and power generation.

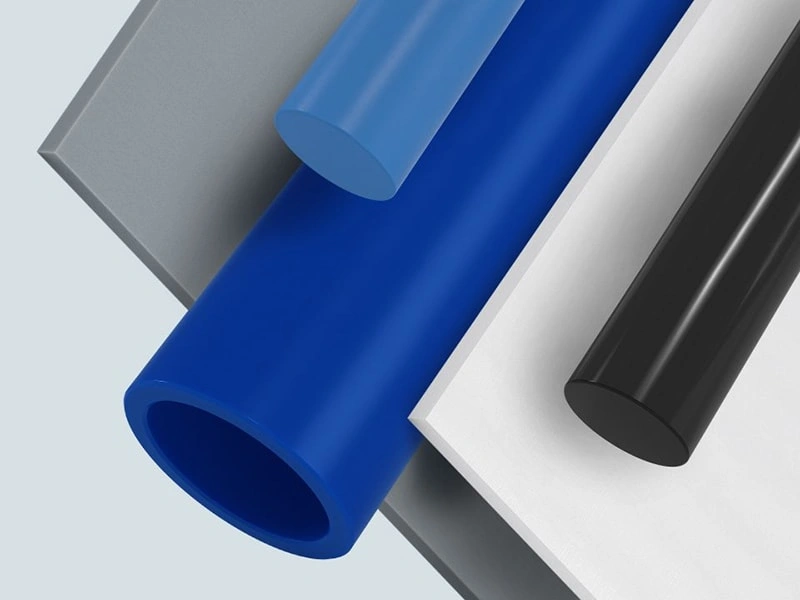

POM is a highly crystalline thermoplastic engineering plastic, which is favored for its high strength, high rigidity, wear resistance and low friction. It is widely used in machinery manufacturing, automobile industry, electronic appliances, medical equipment and other fields, and is known as the "metal in plastic".

Chlorosulfonated polyethylene rubber sheet, also known as Hypalon rubber sheet. It's known for exceptional resistance to chemicals,weathering, and UV resistance. It has an excellent mechanical & good abrasion properties even without reinforcing filters and hasreasonable resilience in grades over 60°shore A. It displays good resistance to heat, ozone, oil and weathering and also gives good adhesion to metal. The recommended operating temperature range is between-40C to +125℃.