Butterfly valve sealing surfaces can be divided into three main categories. What are the characteristics of each category, and how should I choose? Butterfly valve manufacturer WEITEN GROUP, drawing on its successful selection and application experience in tens of millions of projects, has summarized the characteristics and main applications of these three types of sealing surfaces:

PC Sheet has excellent optical properties and a high gloss surface. Easy to fabricate PC shows exceptional performance with a wide operating temperature range (-40°C to +135℃). Other important benefits are high mechanical, thermal ahd electrical properties also virtually unbreakable in normal use. Also available in UV grade.

PVC, also known as polyvinyl chloride in Chinese, is one of the world's most produced general-purpose plastics. PVC rods are made by mixing and extruding PVC resin with stabilizers, lubricants, fillers, plasticizers, colorants, and other additives.

ceramic fiber blanket is a lightweight, flexible insulation material manufactured through a spinning or blowing process of molten alumina-silica compounds. These interlocked fibers form a durable, felt-like blanket offering exceptional thermal resistance in extreme environments.

High-performance butterfly valves utilize a unique triple-eccentric structure, achieving zero friction between the valve disc and the sealing ring. Line-to-surface contact exists during intermediate movement, creating a typical double-seat design.

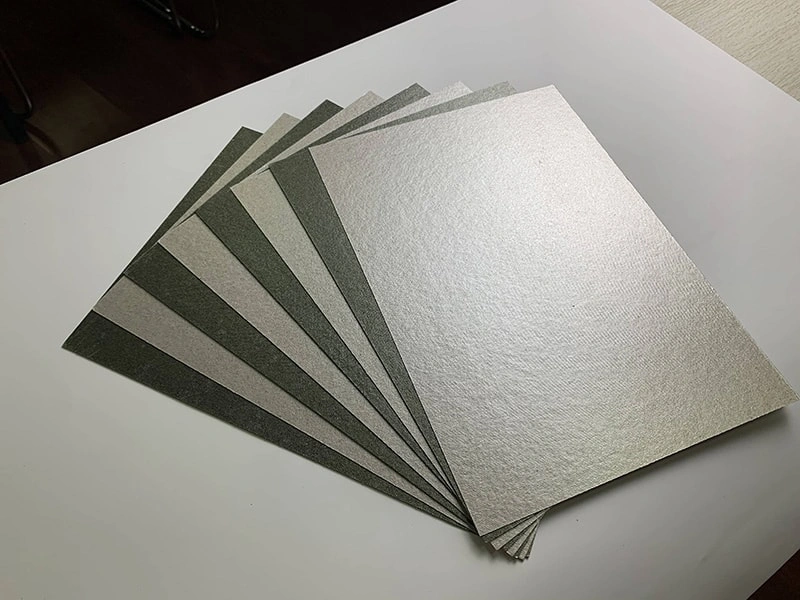

Mica sheet like insulating material made from natural or synthetic mica, combined with a high performance adhesive and processed through a series of processes, including high-temperature and high-pressure processing, baking, and lamination. It perfectly combines the excellent properties of natural mica with the ease of forming modern industrial materials, making it an indispensable and critical insulating material in industries such as electricity, electronics, and metallurgy.