The main material is styrene-butadiene rubber (which may contain fabrics, metal sheets and other reinforcing materials), which is made by vulcanization and has a certain thickness and a large area. It is referred to as styrene-butadiene rubber sheet.

In the complex system of industrial production, sealing materials play a pivotal role, and Kynol packing is one of the most popular ones. With its unique performance advantages, it plays a key role in many industrial scenarios to ensure the stable operation of production.

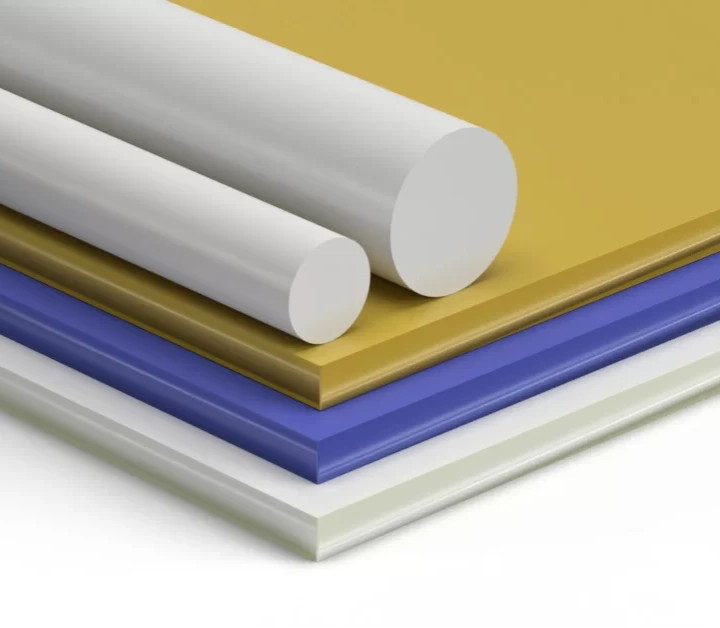

UHMWPE is a high-performance engineering plastic with a higher molecular weight than conventional polyethylene, usually between several million and tens of millions. Due to its unique molecular structure, UHMWPE has excellent physical properties, especially in terms of wear resistance, impact resistance, chemical resistance and self-lubrication.

As an indispensable material in the fields of industry and high-tech, the development prospects of Chloroprene Rubber sheets are promising. Through technological progress and market expansion, Chloroprene Rubber sheets will demonstrate their unique value in more fields in the future, providing more solid material support for the development of related industries.

Fiberglass blanket, full name Fiberglass blanket, is a felt-like material made of glass fiber. Glass fiber is an inorganic non-metallic material with high temperature resistance, good insulation, and corrosion resistance. When countless glass fibers are woven or felted together through a specific process, a Fiberglass blanket is formed.

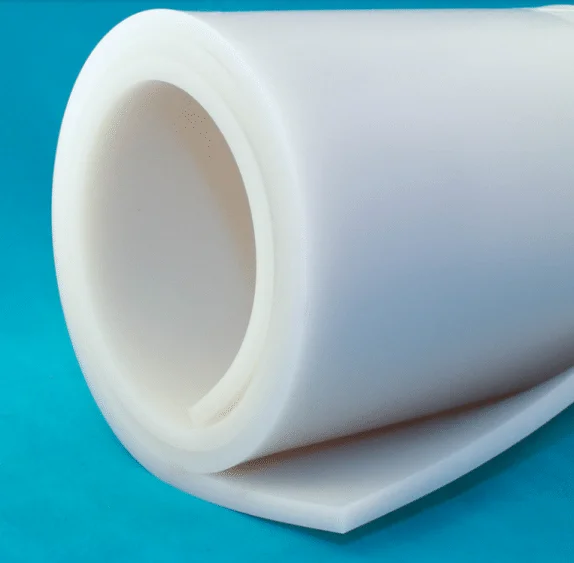

Silicone Rubber Sheet is considered a superhero in the world of rubber sheets. From 3D print molds to body part implants- silicone sheeting is truly the future. They are flexible, durable, and highly resilient.