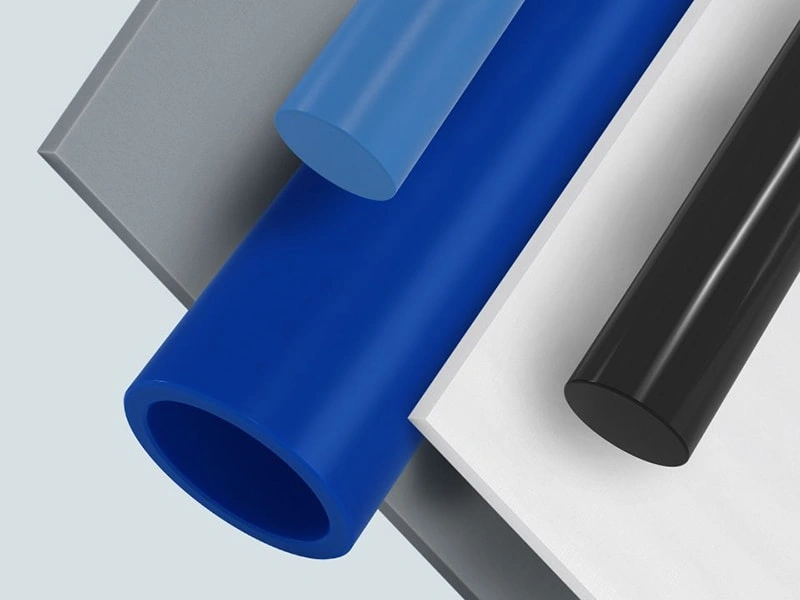

POM is a highly crystalline thermoplastic engineering plastic, which is favored for its high strength, high rigidity, wear resistance and low friction. It is widely used in machinery manufacturing, automobile industry, electronic appliances, medical equipment and other fields, and is known as the "metal in plastic".

High mechanical strength and rigidity: close to metal materials, suitable for high-load, high-precision parts.

Excellent wear resistance and low friction coefficient: strong self-lubricating performance, suitable for friction parts such as gears, slides, bearings, etc.

Good dimensional stability: low water absorption, little affected by environmental humidity, suitable for high-precision applications.

Excellent fatigue resistance: not easy to deform or crack after long-term use, suitable for parts subjected to long-term stress.

Good chemical resistance: strong tolerance to grease, alcohol, gasoline and many solvents.

Excellent processability: easy to injection mold, extrusion and CNC precision processing

Automotive manufacturing: fuel system parts, door locks, seat adjusters, wiper parts, gears and pulleys.

Electronics and electrical appliances: connectors, switches, keyboard keys, precision instrument parts.

Mechanical manufacturing: high-precision gears, cams, rollers, bushings, slide rails, etc.

Medical devices: syringes, surgical instruments, catheter components, dental equipment.

Consumer goods and home appliances: zippers, lighter parts, sports equipment, kitchen mixer parts.

POM is mainly divided into two types:

1.Homo-POM: higher mechanical strength and rigidity, but slightly lower thermal stability.

2.Co-POM: better heat resistance, oxidation resistance and hydrolysis resistance, suitable for more demanding environments.

With the rapid development of industrial manufacturing, lightweight automobiles, intelligent manufacturing, 5G communications and the medical industry, the market demand for POM plastics continues to rise. At the same time, environmental regulations have prompted companies to develop recyclable, low-carbon emission POM materials to meet the needs of sustainable development. In the future, POM is expected to occupy a more important position in the field of high-performance materials.

POM plastics are becoming an important material in the engineering plastics industry due to their excellent mechanical properties and wide range of applications, and will play a greater role in future technological development!

If you would like to find out more about POM or to purchase POM, Please contact us for pricing and conditions. We can provide detailed information and tailor a solution to your needs.

EMAIL:sale@weitengroup.com

MOBILE:+86 18561739639