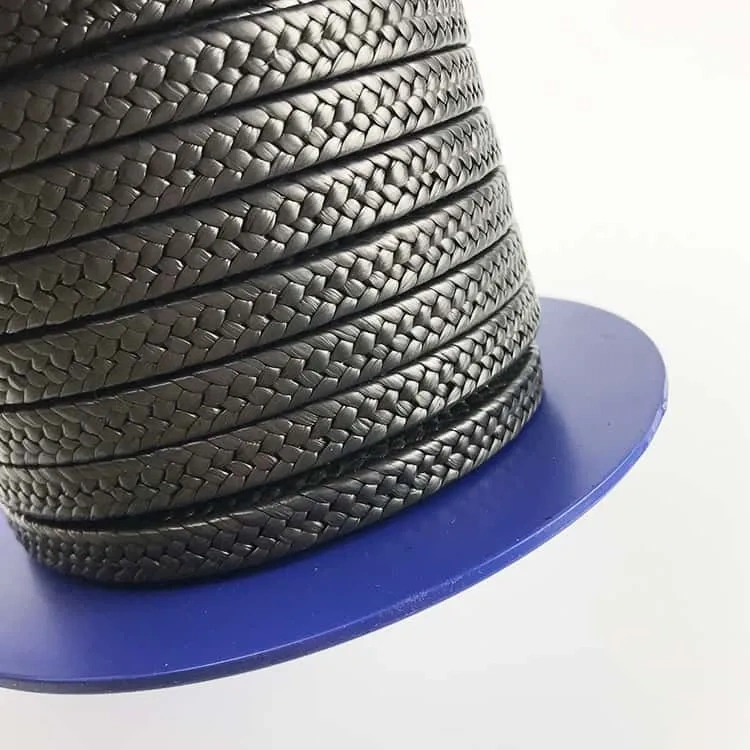

Pure Graphite PTFE Packing is a high-performance sealing material that combines the exceptional chemical resistance and low friction properties of PTFE (polytetrafluoroethylene) with the outstanding thermal conductivity and self-lubricating capabilities of pure expanded graphite. Engineered through an advanced composite manufacturing process, this material delivers superior sealing reliability for dynamic and static applications under extreme conditions, including high temperatures, aggressive chemicals, and high-pressure environments. It is widely used in pumps, valves, mixers, and reactors across industries such as chemical processing, pharmaceuticals, food and beverage, and power generation.

Exceptional Chemical Resistance

Highly resistant to almost all industrial chemicals, strong acids, alkalis, solvents, and oxidizing agents, ensuring long-term stability in corrosive media.

Excellent Thermal Stability

Suitable for a wide temperature range from -200°C to +280°C (short-term up to 300°C), with no degradation or hardening under cyclic thermal conditions.

Outstanding Self-Lubrication & Low Friction

The PTFE and graphite composite structure provides a low coefficient of friction, reducing shaft wear and energy consumption in rotating equipment.

High Thermal Conductivity

Graphite content enables efficient heat dissipation from the sealing interface, preventing overheating and extending packing and equipment life.

Flexible and Easy to Install

Can be cut, wound, or molded on-site without special tools, supporting quick maintenance and reduced downtime.

Environmentally Safe and FDA-Compliant

Free from asbestos and heavy metals, suitable for use in food, pharmaceutical, and drinking water applications.

Item Description | |

Cross-sectional Shape: | quare, rectangular, twisted, braided |

Cross-sectional Dimensions: | 3mm–50mm (custom sizes available) |

Length: Packing: | 3–100 meters per coil (cut-to-length or custom gaskets available) |

Color: | Natural white (PTFE-based), gray (graphite-blended) |

Reinforcement: | Can be reinforced with aramid fibers, glass fibers, or Inconel wire for higher pressure applications |

Performance | Unit | Typical Value |

Density | g/cm³ | 1.7–2.0 |

Continuous Operating Temperature | °C | –200 to +280 |

Thermal Conductivity | W/m·K | 5–15 |

Acid and Alkali Resistance Range(pH) | — | 0–14 |

Coefficient of Friction | — | 0.05–0.15 |

Compression Recovery Rate | % | ≥ 85 |

Chemical & Petrochemical: Seals for reactors, agitators, centrifugal pumps, and acid valves

Pharmaceutical & Food: Aseptic mixers, filling machines, CIP/SIP systems, and sanitary valves

Power Plants: Boiler feed pumps, steam valves, and heat exchanger flanges

Water & Wastewater Treatment: High-pressure pump seals, mixer shafts, and diaphragm valves

General Industry: Rotary joints, expansion joints, and flange gaskets in OEM equipment

Pure Graphite PTFE Packing represents a significant advancement in sealing technology, offering a balanced profile of chemical inertness, thermal resilience, and maintenance-friendly performance. Its adaptability across both traditional and high-tech industries makes it a go-to solution for engineers seeking durable, reliable, and efficient sealing in challenging operating conditions.

If you would like to find out more about Pure Graphite PTFE Packing or to purchase other products, please contact us at sales@weitengroup.com, wwww.weitengroup.com.