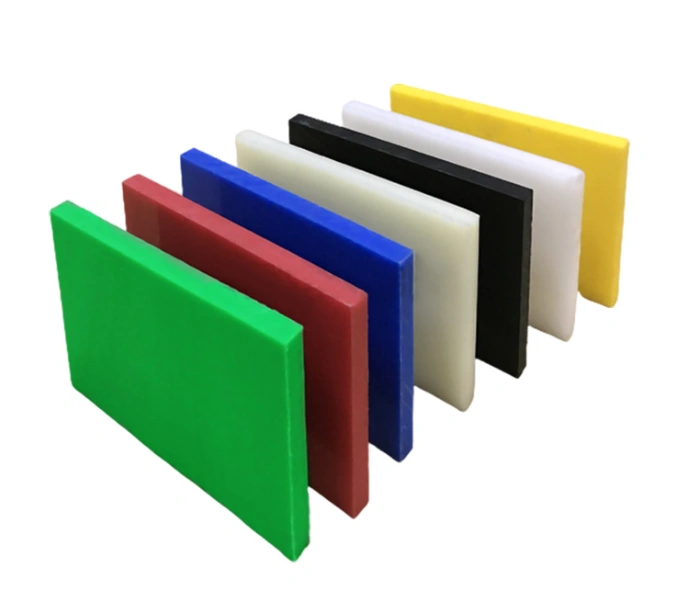

High-density polyethylene (HDPE) sheets are an important plastic material widely used in many fields. Its excellent performance and diverse characteristics make it an ideal choice in engineering applications. This article will explore the characteristics, manufacturing process, application areas, and advantages of high-density polyethylene sheets to provide a better understanding and utilization of this material.

1. Characteristics of high-density polyethylene sheets

1. High Density: Compared to other polyethylene materials, high-density polyethylene sheets have a higher density, thus possessing higher strength and rigidity.

2. Corrosion Resistance: high-density polyethylene sheets exhibit excellent corrosion resistance and can be used for extended periods in harsh environments such as those containing acids and alkalis without damage.

3. Excellent Electrical Insulation Properties: Due to their good electrical insulation properties, high-density polyethylene sheets are widely used in electrical engineering.

4. Abrasion Resistance: high-density polyethylene sheets have good abrasion resistance and can maintain a good surface condition in high-friction environments.

2.Manufacturing process of high-density polyethylene sheets

High-density polyethylene (HDPE) sheets are primarily manufactured using the extrusion method. First, HDPE granules are heated and melted. Then, the molten polyethylene is extruded into a sheet shape through an extruder. Next, it is rapidly cooled and solidified using a cooling device, followed by cutting and shaping to obtain the desired sheet dimensions.

3.Applications of high-density polyethylene sheets

1. Chemical industry: Used in the manufacture of chemical equipment, storage tanks, pipelines, etc., its corrosion resistance and excellent physical properties are highly valued.

2. Power industry: Used in the production of electrical equipment insulation materials, insulation boards, insulation gaskets, etc., possessing good electrical insulation and high-temperature resistance.

3. Food industry: Used in the manufacture of food packaging, food processing equipment, etc., widely used due to its non-toxic, hygienic, and corrosion-resistant properties.

4. Construction industry: Used in the production of thermal insulation materials, roof waterproofing materials, basement moisture-proof materials, etc., possessing good weather resistance and durability.

5. Agricultural industry: Used in the manufacture of greenhouses, water conservancy projects, feed troughs, etc., favored by farmers due to its corrosion resistance, weather resistance, and ease of cleaning.

4.Advantages of high-density polyethylene sheets

1. Environmentally Friendly and Sustainable: High-density polyethylene (HDPE) sheets are recyclable materials, meeting the requirements of environmental protection and sustainable development.

2. Lightweight and High-Strength: Compared to metal materials, HDPE sheets have a lower density while possessing excellent strength and rigidity, meeting various engineering needs.

3. Corrosion and Abrasion Resistant: HDPE sheets have excellent corrosion and abrasion resistance, enabling long-term stable operation in harsh environments.

4. Easy Processing: HDPE sheets are easy to cut, drill, weld, and mold, meeting the needs of various shapes and sizes.

5. Excellent Insulation Performance: HDPE sheets possess good electrical insulation properties, playing an important role in the field of electrical engineering.

If you would like to find out more about high-density polyethylene sheets or to purchase other products, please contact us at sales@weitengroup.com, wwww.weitengroup.com.