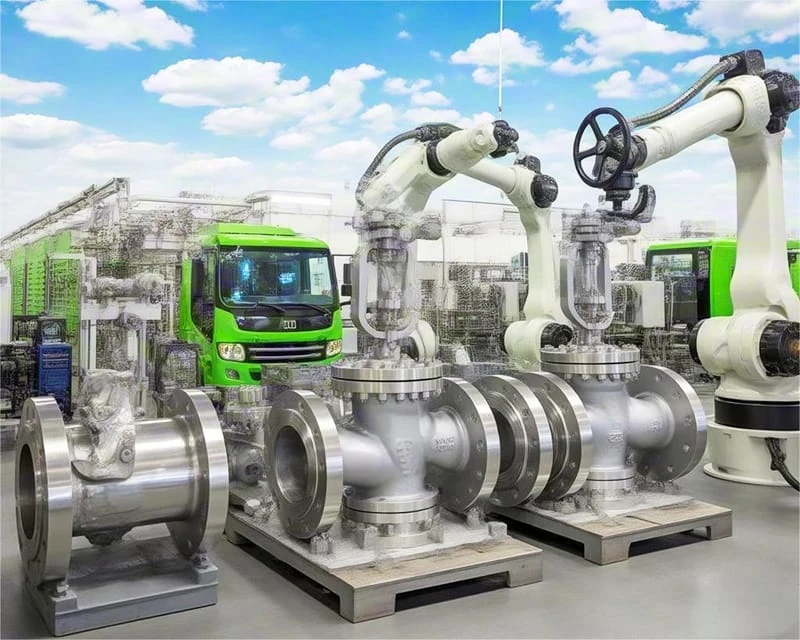

In the vast industrial world, fixed ball valves have become an indispensable and important part of the field of industrial fluid control with their unique structure, excellent performance and wide application fields.

1.Working principle and structural characteristics of fixed ball valves

As the name suggests, the valve core (ball) of a fixed ball valve is fixed in the valve body and will not move with the rotation of the valve stem.

The structure of a fixed ball valve mainly includes valve body, ball, valve seat, valve stem, stuffing box, drive device and other parts.

The valve body is usually made of cast steel, forged steel, stainless steel and other materials to meet the fluid pressure and temperature requirements under different working conditions.

The ball is made of alloy steel or stainless steel of different materials according to the medium characteristics and working pressure to ensure its strength and corrosion resistance.

The valve seat is generally made of elastic materials such as PTFE, rubber or metal sealing ring, which fits closely with the ball to form an effective seal.

2. Performance advantages of fixed ball valves

Excellent sealing performance: The valve seat of a fixed ball valve is usually made of elastic material, which has excellent wear resistance, corrosion resistance and temperature resistance. When the ball is rotated into place, the valve seat can fit the ball tightly to form a reliable seal.

Extremely low fluid resistance: The internal channel of the ball of the fixed ball valve is designed as a straight-through type, and the fluid will not be subject to additional obstacles when passing through, so it has extremely low fluid resistance.

3. Application fields of fixed ball valves

Petroleum and natural gas industry: In the process of oil and gas extraction, transportation and processing, fixed ball valves are widely used in key parts such as wellhead devices, oil refining equipment, and transportation pipelines.

Chemical industry: In chemical production, fixed ball valves are often used to control corrosive media.

Power industry: In the power industry, fixed ball valves are used in cooling water systems, boiler feed water systems, heat transfer systems and other parts.

Water treatment industry: In the water treatment industry, fixed ball valves are widely used in water plants, sewage treatment plants and other occasions.

Food processing industry: In the food processing industry, fixed ball valves are often used in sanitary fluid control systems, such as production lines for beverages such as milk, juice, and beer.

4. Maintenance and care of fixed ball valves

Regular inspection: Regularly inspect fixed ball valves, including valve stems, stuffing boxes, sealing surfaces, etc., to ensure that there is no leakage, no rust, and no damage.

Cleaning and lubrication: Regularly clean fixed ball valves to remove sediment and impurities. At the same time, lubricate parts such as valve stems and stuffing boxes to reduce friction and wear.

Replacement of seals: When a fixed ball valve is found to have a leakage problem, the seal should be replaced in time. When replacing, ensure that the new seal cooperates well with the valve seat and ball to form an effective seal.

Maintenance of the drive device: For fixed ball valves with pneumatic, electric, and other drive modes, the drive device should be regularly inspected and maintained to ensure its normal operation.

Repair and replacement: When a fixed ball valve fails or is damaged, it should be repaired or replaced in time. During maintenance, the operating procedures should be strictly followed to ensure the quality of maintenance. If it cannot be repaired, a new valve should be replaced in time.

5. Conclusion

With its unique structure, excellent performance and wide application field, the fixed ball valve has become an indispensable and important part of the industrial fluid control field. With the continuous advancement of technology and the continuous changes in the market, the fixed ball valve will continue to develop in the direction of more efficiency, intelligence and environmental protection.