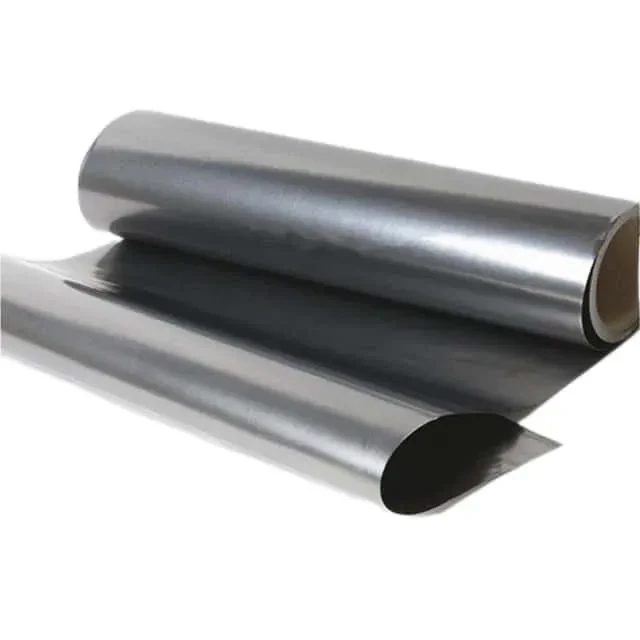

Flexible graphite sheet are a sheet material made from high-purity graphite that has been chemically treated and expanded at high temperatures before being pressed. They retain graphite's excellent thermal conductivity and chemical stability while also offering good flexibility and compressibility, making them ideal for applications such as industrial sealing, thermal management, and electromagnetic shielding.

Horizontal thermal conductivity: 300–500 W/(m·K), far exceeding copper and aluminum, suitable for efficient heat dissipation

Vertical thermal conductivity: 5–10 W/(m·K), preventing the formation of localized hot spots

Strong heat distribution: Suitable for temperature equalization in high-power electronic equipment

Oxidizing Environments: Long-term stable operating temperature up to 450°C

Inert/Vacuum Environments: Withstands up to 3000°C

Thermal Shock Resistance: Resists cracking under rapid temperature changes

High Compression Resilience: Compression rate exceeds 40%, rebound rate >90%

Low Creep: Maintains sealing performance even after prolonged compression

Adapts to Irregular Surfaces: Fills even small bumps and indentations, ensuring reliable sealing

4. Chemical Stability: Resistant to acids, alkalis, and organic solvents

Radiation Resistance: Suitable for nuclear equipment

No aging issues, long service life

Volume Resistivity: 0.001–0.01 Ω·cm

Effectively shields high-frequency electromagnetic interference

Pipe Flange Seals: High-temperature and corrosion-resistant, suitable for petrochemical applications

Engine Cylinder Gaskets: Reduce the risk of fuel leaks

Valve Seals: Suitable for high-pressure, high-wear environments

5G Base Station Heat Dissipation: Replaces metal heat sinks, reducing weight

Power Battery Thermal Management: Improves electric vehicle safety

LED Lighting Heat Dissipation: Extends service life

Fuel Cell Bipolar Plates: Improves conductivity and corrosion resistance

Semiconductor Equipment Heat Dissipation: Heat dissipation in wafer manufacturing

Photovoltaic Module Thermal Conductivity: Improves solar panel efficiency

Rocket Engine Seals: Withstands extreme temperatures

Satellite Thermal Control Systems: Regulate cabin temperature

Electromagnetic Shielding: Protects precision electronic equipment

Can be cut with scissors, lasers, or water jets

Can be stamped into complex shapes (such as gaskets and seals)

Adhesive backing for easy fixing

Contains no asbestos, halogens, or other hazardous substances

RoHS/REACH compliant

Recyclable, reducing industrial waste

Long service life, requiring less frequent replacements

Overall performance outperforms traditional metal or rubber sealing materials

Application Scenario Recommended Thickness Recommended Type

Electronic Heat Dissipation 0.1–0.5mm Ultra-Thin High Thermal Conductivity

Industrial Sealing 0.5–3mm Enhanced Compression Resilience

High-Temperature Environment 1–6mm Oxidation-Resistant High-Purity Graphite

Installation: Apply even pressure to avoid localized over-compression

Storage: Keep dry to prevent oxidation

Maintenance: Regularly check seals and replace if necessary

Innovative Composite Materials

Graphite + Metal Mesh (Increased Mechanical Strength)

Graphite + Ceramic Coating (Enhanced Oxidation Resistance)

Flexible graphite sheet, with its unique thermal conductivity, sealing, and temperature resistance, has become an indispensable key material in modern industry. With the rapid development of new energy, semiconductor, and 5G technologies, market demand is expected to continue to grow. In the future, higher-performance composite graphite materials will further promote industrial technological advancement.

If you would like to find out more about flexible graphite sheet or to purchase other products, please contact us at sales@weitengroup.com, wwww.weitengroup.com.