1. Basic Concepts

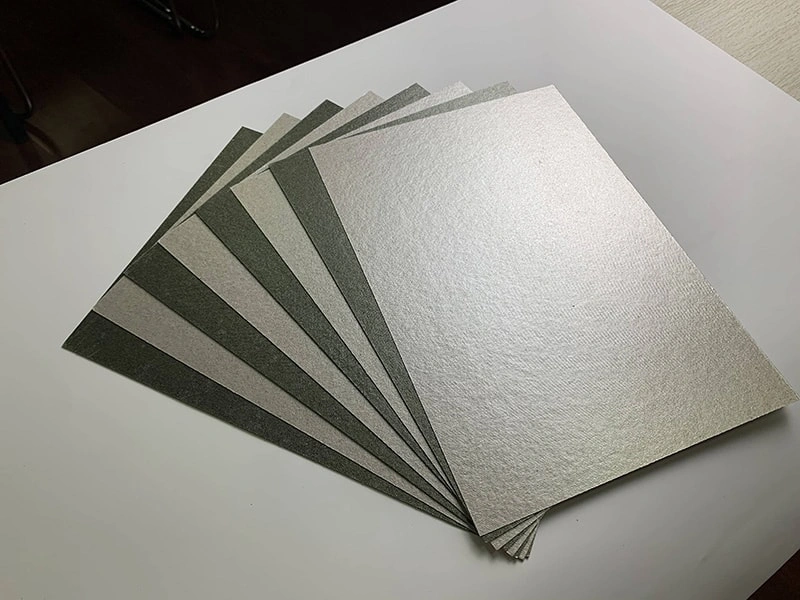

Mica sheet like insulating material made from natural or synthetic mica, combined with a high performance adhesive and processed through a series of processes, including high-temperature and high-pressure processing, baking, and lamination. It perfectly combines the excellent properties of natural mica with the ease of forming modern industrial materials, making it an indispensable and critical insulating material in industries such as electricity, electronics, and metallurgy.

2. Advantages of Mica Sheet

Mica sheets are widely used due to their exceptional physical and chemical properties:

Extremely high electrical insulation strength: Mica itself is an excellent natural insulator, and mica sheets made from it possess high dielectric strength and insulation resistance, effectively preventing breakdown.

Excellent high-temperature resistance: This is one of mica sheets' most prominent advantages. They do not burn or carbonize at high temperatures, and their long-term operating temperature can range from 130°C to over 1000°C, depending on the adhesive.

Excellent mechanical strength: With high bending and compressive strength, they are particularly suitable for applications requiring high mechanical stress, such as motor slot insulation.

Excellent arc and corona resistance: Phlogopite mica sheets excel in this regard, effectively resisting the erosion of high-voltage arcs and corona.

Excellent chemical stability: They are resistant to acids, alkalis, and corrosion, insoluble in most solvents, and have good environmental adaptability.

Low-smoke, halogen-free, and environmentally safe: In environments with high fire risk, mica boards emit very low smoke and release no toxic halides, meeting modern environmental and safety requirements.

Excellent thermal conductivity: It provides both insulation and excellent thermal conductivity, helping to dissipate heat from electrical equipment.

3.Main Application Areas

Mica sheets are used in nearly all industrial applications requiring high-temperature insulation:

Household Appliances: Gasket insulation for heating components in electric irons, hair dryers, microwave ovens, ovens, toasters, fan heaters, electric kettles, and other appliances.

Metallurgy and Chemical Industry: Furnace lining insulation for smelting equipment such as power frequency furnaces, medium frequency furnaces, and electric arc furnaces, as well as high-temperature sealing and insulation in chemical equipment.

New Energy Vehicles: Thermal insulation and fireproof covers for power battery modules (mica sheets are the core material), as well as insulation for drive motors and on-board chargers (OBCs).

Industrial Motors and Electrical Appliances: As a core material for motor insulation, they are used in:

Slot Insulation: Placed within the stator or rotor core slots, separating the coils from the core.

Phase-to-Phase Insulation: Isolates coils of different phases.

Interlayer Insulation: Used between coil turns.

Commutator Insulation: Used for insulation between segments in DC motor commutators.

Aerospace and military industry: Used for insulation of electrical systems of aircraft engines, missiles, satellites and other equipment that require extremely high reliability and temperature resistance.

If you would like to find out more about Mica Sheets , please contact us at weiten@weitengroup.com, wwww.weitengroup.com.